With a large scale of 80,723 m2 and a capacity of 4 billion units of products per year, DHG Pharmaceutical plant is always in the top modern one in the country. However, the most notable thing is that this plant owns up to 2 lines meeting Japan-GMP standard.

The largest plant owns Japan-GMP line

Japan-GMP standard is certified by the Japan Pharmaceuticals and Medical Devices Agency (PMDA), which has been currently pursued by many domestic pharmaceutical companies. However, the country has only 3 enterprises with their plants owning production lines meeting Japan-GMP standard

According to the Drug Administration of Vietnam, these three plants include DHG Pharma, Rohto-Mentholatum and Mekophar. In which, DHG pharmaceutical equipped with 2 lines meeting Japan-GMP standard.

DHG Pharma has been equipped with 2 production lines meeting Japan-GMP standard

DHG Pharmaceutical plant, located in Lot B2-B3, Tan Phu Thanh Industrial Park (Hau Giang province), was built in 2011 with a total investment of VND599 billion and put into operation since 2014 with a total capacity of 5 billion units of products per year. The plant is built self-contained with 3 betalactam factory, non-betalactam factory, packaging printing workshop and office building.

In which, the 9,289 m2 non-betalactam workshop plays an important role, owning 2 lines of tablets and film-coated tablets of Japan-GMP standard which were recently published. The factory has a maximum capacity of 4 billion units of products per year, in 2020 has reached an actual capacity of 3.36 billion units. This key factory cluster currently produces 211 out of 306 products in the whole plant, including nearly 100 products are produced on 02 lines of tablets and film coated tablets meeting Japan-GMP standards.

What's special about these two Japan-GMP lines?

The operation way of Japan-GMP line is always a matter of great concern and understanding. In fact, whether in Vietnam or Japan, Japan-GMP standard medicines must be "born" with the same extremely strict international standards.

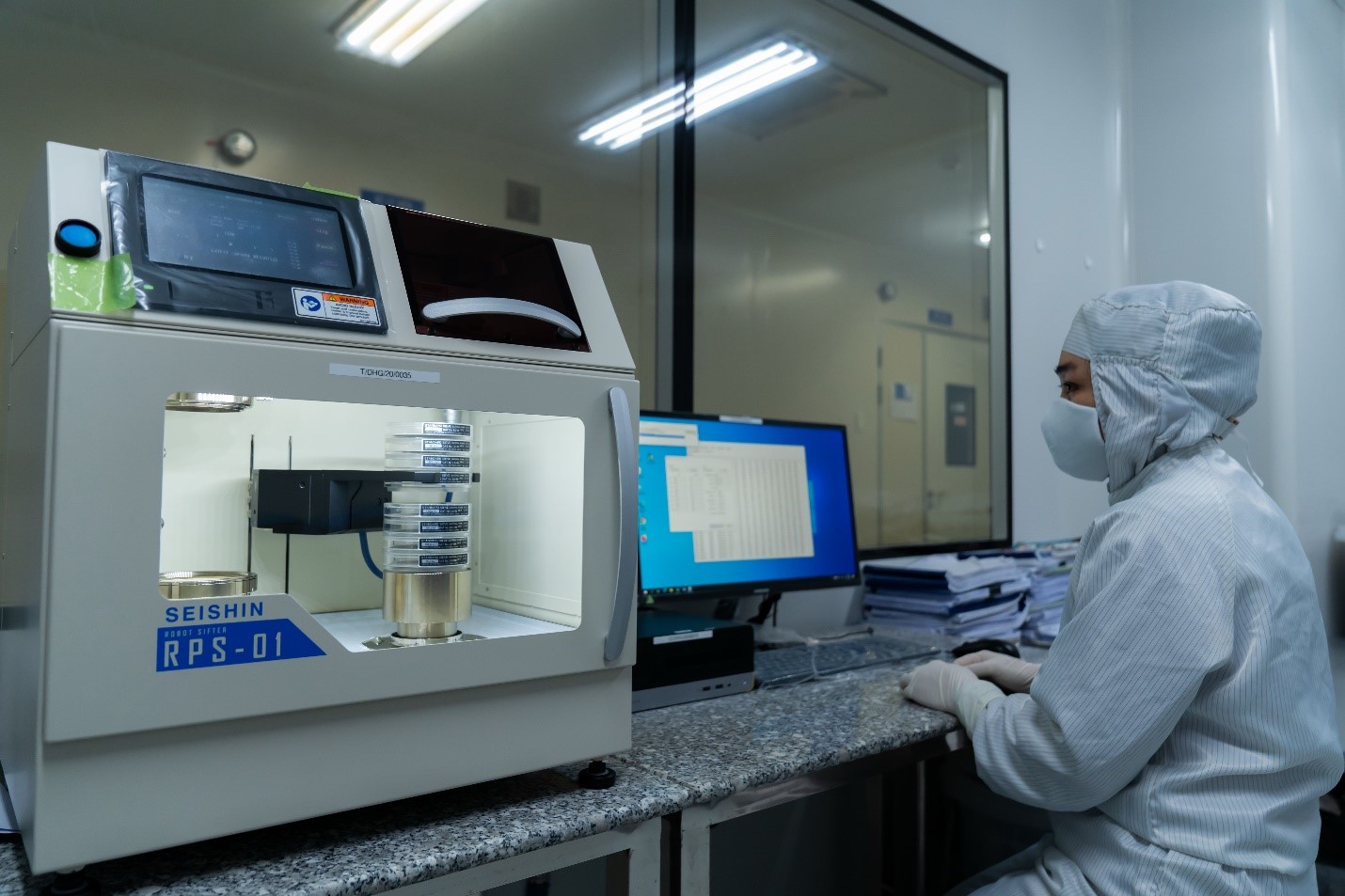

Inside 2 lines are 32 massive and modern machinery equipment with many high-speed mixers, fluid bed dryers, cube mixers, tablet press, automatic tablet counting machine, blister packing machine, film coating machine, etc. controlled automatically. The most overwhelming is high-power tablet press with modern tablet pressing technology, automatic powder supply, self-control of technical criteria of tablets with perfect accuracy.

Japan-GMP production process must ensure the highest accuracy.

Mr. Tomoyuki Kawata - Deputy General Director of DHG Pharmaceutical JSC said that Japan-GMP's characteristic is a high cost of equipment investment. With this series of machines, each year, Japan-GMP tablet production line reaches nearly 2 billion units for more than 40 products. Meanwhile, the film-coated tablet production line is responsible for producing nearly 1 billion units for the remaining products. In order to achieve such tremendous performance, both lines now have to operate continuously 3 shifts with optimal production plan to reduce product conversion hours.

In addition to the modern invested machinery equipment, the company always pays attention to the quality human resources. The staff is trained to achieve the good qualification and workmanship, and always consciously comply with the regulations. DHG Pharma has sent 6 management personnel to the Taisho – Japan company for intensive training in quality system, controlling and product development researching while other technicians are trained by Japanese engineers to improve their qualifications directly at DHG Pharmaceutical Factory or through regular online meetings. All of these works are to provide the products guaranteed with the best quality into the market

In addition to ensuring product quality in the production process, DHG Pharma also ensures product quality through strict control according to the process of meeting high quality standards at all relevant stages from the purchase of raw materials, input packaging to the stages of import - export the warehouse and distribution of finished products. Therefore, in addition to the factory with production line meeting Japan-GMP standards, DHG Pharma also has a warehouse and distribution system which meets the GSP and GDP standards. All of these ensure that the products always meet the best quality when they reach to the consumers.

Many other "Japan-GMP know-how" are also transferred by Taisho to DHG Pharma, including management process and strict production schedule charactered by Japan. For example, in order to facilitate order-based production, the company plans to supply goods from 6 months to 1 year, applying “Just in Time” method to have best MOH inventory turnover while still meeting the market demand well.In addition to the finished products produced on Japan-GMP line, the company also has its own packaging factory, providing full and timely quantity required by the standardized "Just in Time" method for the whole factory.

Pharmaceutical quality is always a key issue, deciding sold medicine output not only in the domestic market but also export sales of high-quality products to the world. Currently, in addition to serving the domestic channel, these 2 Japan-GMP lines also produce for the market of 14 countries and process for foreign partners who are Japanese pharmaceutical companies.